Zimmer® also offers adaptable technology to produce a variety of polymers such as PCT, TPEE, PEN or PET containing various additives and co-monomers.

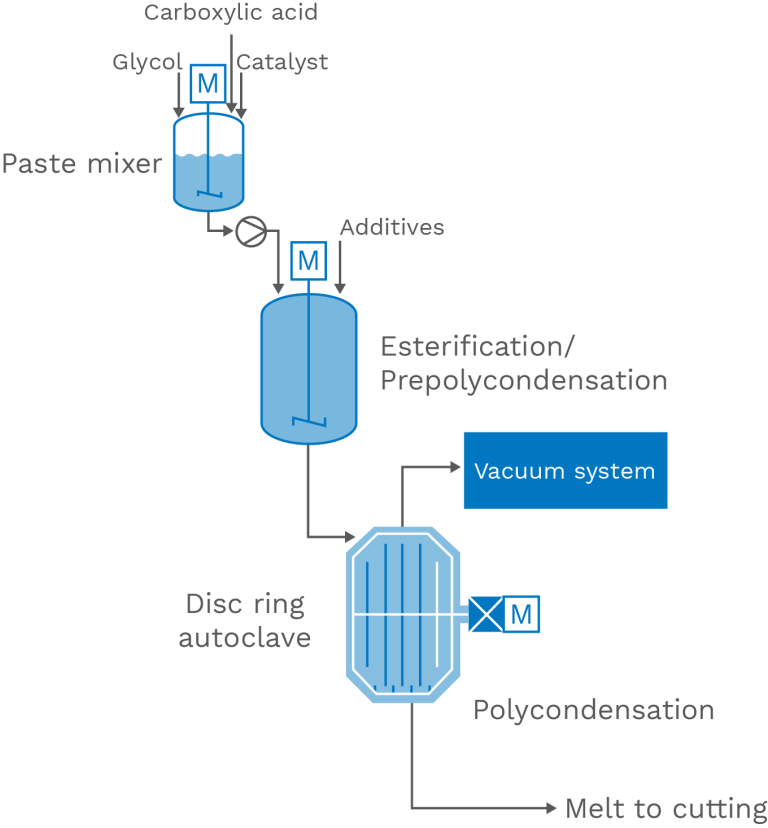

The specialty polyesters are based on a carboxylic acid and glycol as main feedstock. Both are mixed while catalyst/ additives are added in the paste preparation vessel. From there the paste is fed into the Esterification/Prepolymerization reactor. This step is controlled using a special temperature/pressure regime and additives can be fed as required per recipe.

The split-off vapors are released from the esterification stages and fed into the process column for rectification. The intermediate polymer product is then transferred to the Disc Ring Autoclave for final polymerization.

This proprietary reactor enables a maximum evaporation surface due to high surface renewal, low process temperature, short polycondensation time and therefore low thermal stress.

Contact Our Experts

Thomas Brauburger

Director Sales

Dr. Marius Hackel

Head of Product Management and R&D

Tel: +49 (0) 69 667784 500